Manufacturing Capabilities

Capabilities. Flexibility. Efficiencies. They’re all aspects of the manufacturing process that can have an impact on the success of your production plan.They also happen to be three of our strengths, which you can leverage by collaborating with the team at E. Hofmann Plastics Inc., for:

Thermoforming

- Currently produce over 21 million thermoformed parts per week

- Stock or custom designs

- Trim-in-place forming process for precision parts

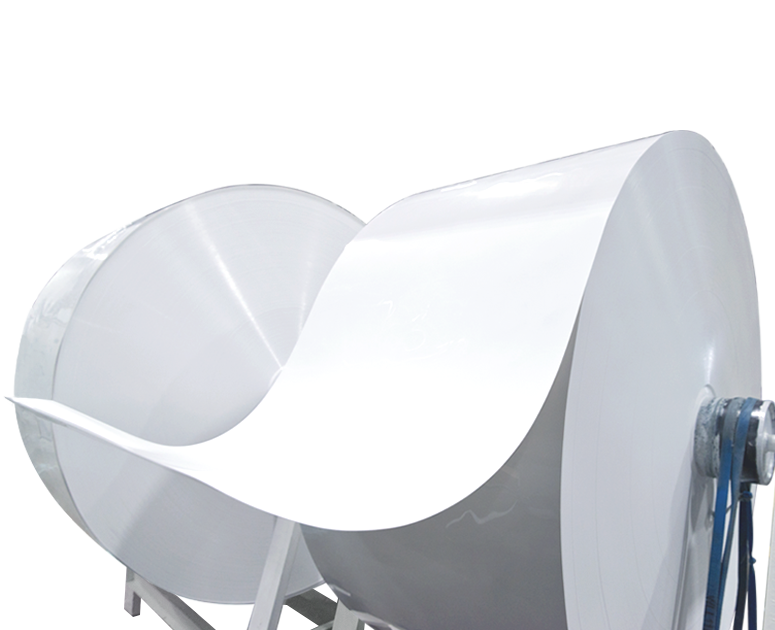

Co-Extruded Sheet

- Seven layers of polypropylene

- Ability to have an oxygen barrier

Injection Moulding

- 25 injection moulding machines, ranging from 90 to 500 ton

- We produce over 80,000 injection moulded parts per day

- Custom coloured pails, lids and handles

Labeling

Your brand matters. You’ve invested a great deal of time and money in developing and promoting it. When consumers walk down the aisles, it’s the look and feel of the label on your product that reinforces what your brand represents and stands for. That’s why the colours and alignment must be true to the original design. At E. Hofmann Plastics Inc. we print labels with the same expectation we have for the products we produce—to be flawless.

If you’re in need of branding or package design E.Hofmann Plastics recommends our trusted agency partner UNITE. Click here for more information.

- Eight printing lines allowing container decorating with as much as nine colours for small containers and six colours for our biggest pails

- Dry offset, heat transfer, emulsion and sleeve labeling

- In-mould labelling and heat transfer labelling used to decorate containers